Are you beginning to think your project may be a total wreck? Is it way over budget? And does anybody but you care about that? Does it bother anybody that there’s no end in sight? And feature-creep never seems to end? If so, that’s a sign that your project has gone off the rails, and is doomed for failure.

Chances are you’re not the only one who’s noticed.

A dark cloud of failure sometimes descends upon project from time to time. I’m not sure if anybody really knows why. It just happens. I suppose you could call it a “perfect storm” of incompetence, wrong choices, and apathy. When those circumstances form up into that dark cloud over your project, forget it! You’re done!

This begs the question of whether there should be an assigned person whose responsibility it is to watch for telltale signs of failure. Such a person should first of all have been involved in a few epic failures so he knows the signs. Peering into the hazy fog doesn’t do anybody any good.

Here are some signs to look for:

Missing half your milestones

If your project is consistently blowing past half the milestones (evaluation points), then you clearly haven’t identified all the work required. And if that’s the case, your project may last 2 – 3 times longer than expected. Is that okay? Can the budget hold that much water?

Cynical Team Members

Are your project team members gossiping about management? Has water cooler talk all gone negative? If so, the team may have lost its moral. Employees can’t always pinpoint the problems, but they sure can gripe. If that’s happening a lot, then you project may be in trouble.

No End In Sight

Can team members see the light at the end of the tunnel? Are you making progress, or just spinning your wheels. You had better see some progress or you might be in a death march.

The Death March

This is when overtime rises to 60 – 80 hours per week. You’re working weekends to meet a vague deadline that has no obvious payoff. And you get the distinct impression that you’re still climbing the hill rather than sledding down the other side. Project leads say you’re just about finished, but you get the sense that that isn’t true. Why else would the work keep piling up?

Pulling Out

As we said earlier, the only way to pull out of the situation like this is for a whistleblower to call it. Do you have one on your team? If so, chop the product into quarters. Deliver what little you have done now. Take a big break. And then take up the monumental challenge of boiling the ocean. Maybe your project is just four times bigger than you first imagined.

A Helpful Timesheet Product: Standard Time®

Here’s a link to YouTube video that could help. This is a timesheet project that may have a few answers, and may impose some order to your project. It’s worth a look.

http://www.youtube.com/watch?v=SJRKTBye2j4

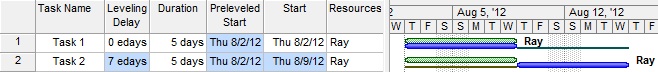

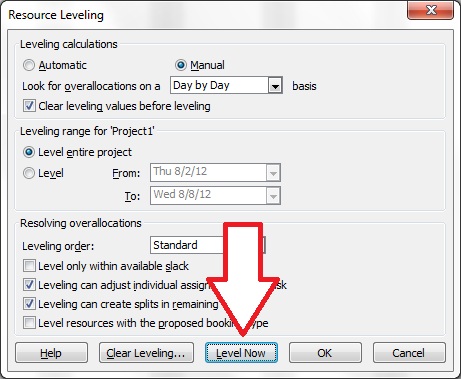

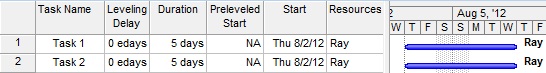

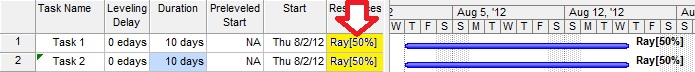

Multitasking means working both tasks during the same calendar date range

Multitasking means working both tasks during the same calendar date range